Carbon pore potion SCC-66/67/68

Introduction to Carbon pore potion SCC-66/67/68 products

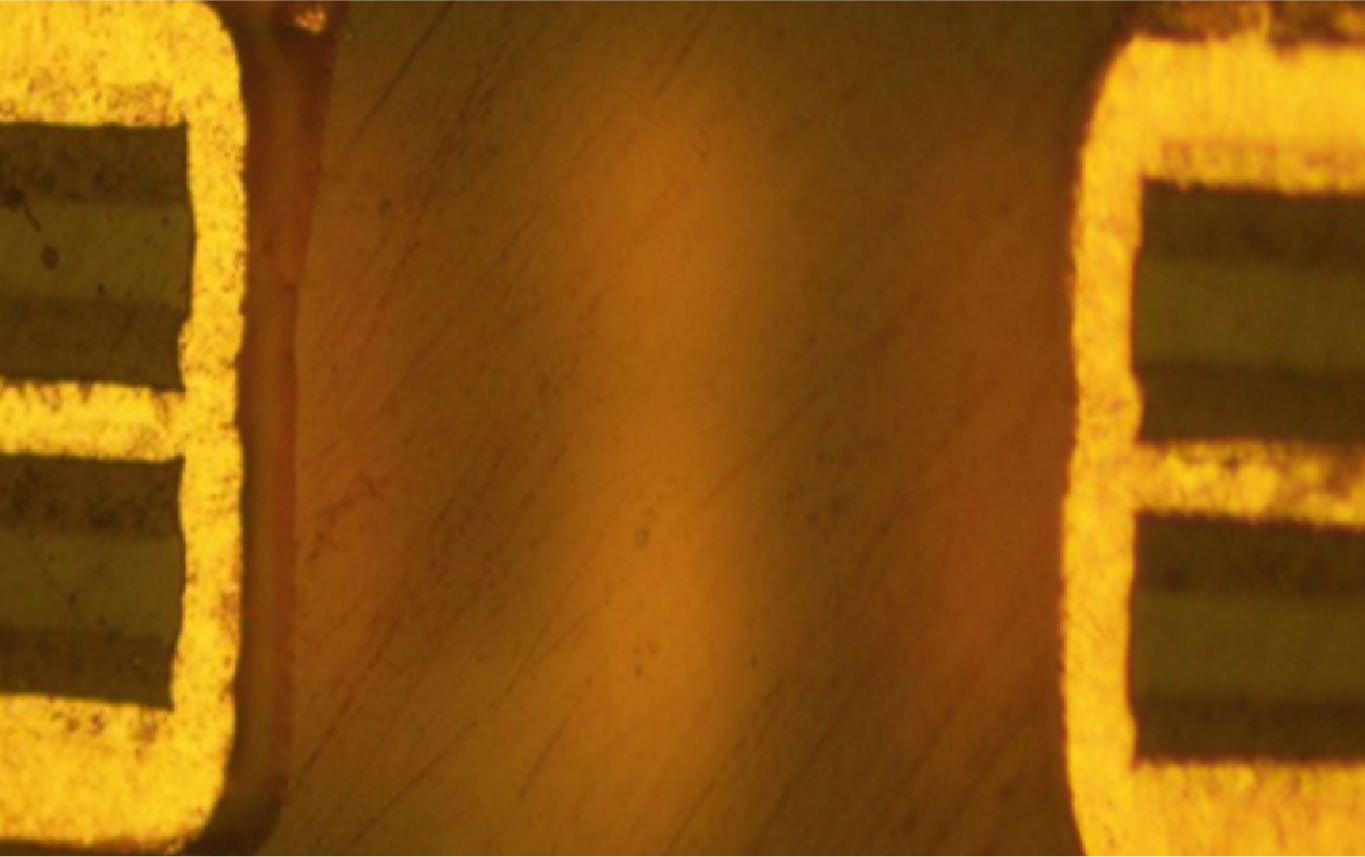

Product Features

Horizontal process,effectively resolves wrinkling issues.

Environmental protection, no volatile harmful substances; And the treatment of carbon hole waste liquid is very simple and environmentally friendly

Slowly add 35% hydrochloric acid (10-15 liters of hydrochloric acid per 200 liters of tank liquid) and stir slowly until no foam is formed

After standing there, the solid-liquid is separated, and the supernatant is discharged to the conditioning tank, and the precipitate can filter out the water

High number of bending tests (some customers require 200,000 bending times, and carbon hole process can easily reach 300,000 times)

Short process cycle, reducing delivery time.

Process Parameters

It has easy-to-clean carbon hole process technology, and after using it with a special cleaning agent, the surface can be rinsed clean by controlling the amount of micro-corrosion by 0.5μm, which is especially suitable for multi-layer flexible boards and rigid-flexible boards.

The products have been widely used in automotive, electronic consumer, packaging substrates, camera cables and other types of sheet materials.

Continue to develop carbon hole process for rigid and flexible panels

Use special cleaning and whole hole tank fluid, and adjust the charge of glass fiber, resin and PI at the same time to improve the conductivity effect, and effectively prevent excessive resistance caused by uneven copper thickness and copper in a single hole